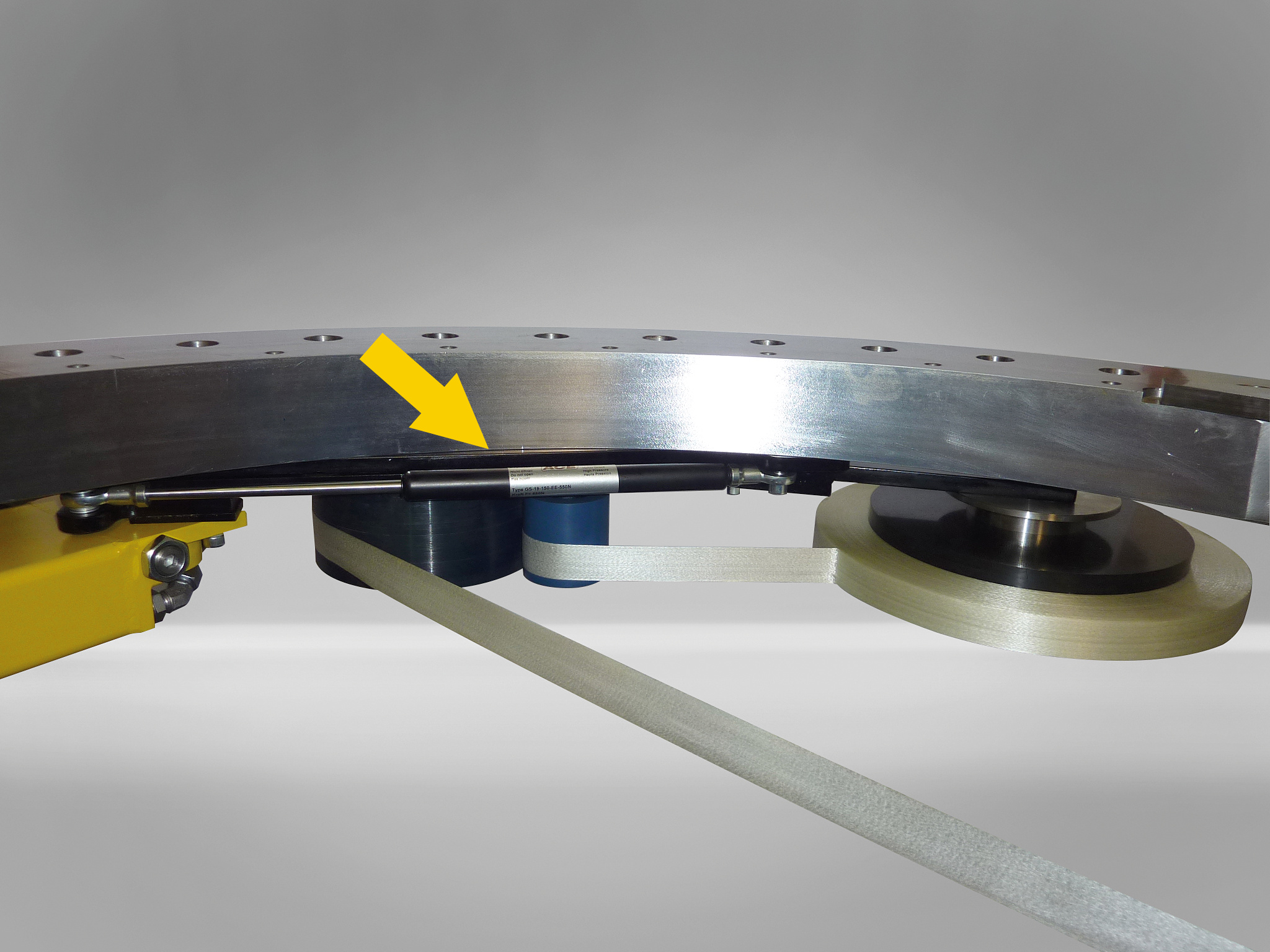

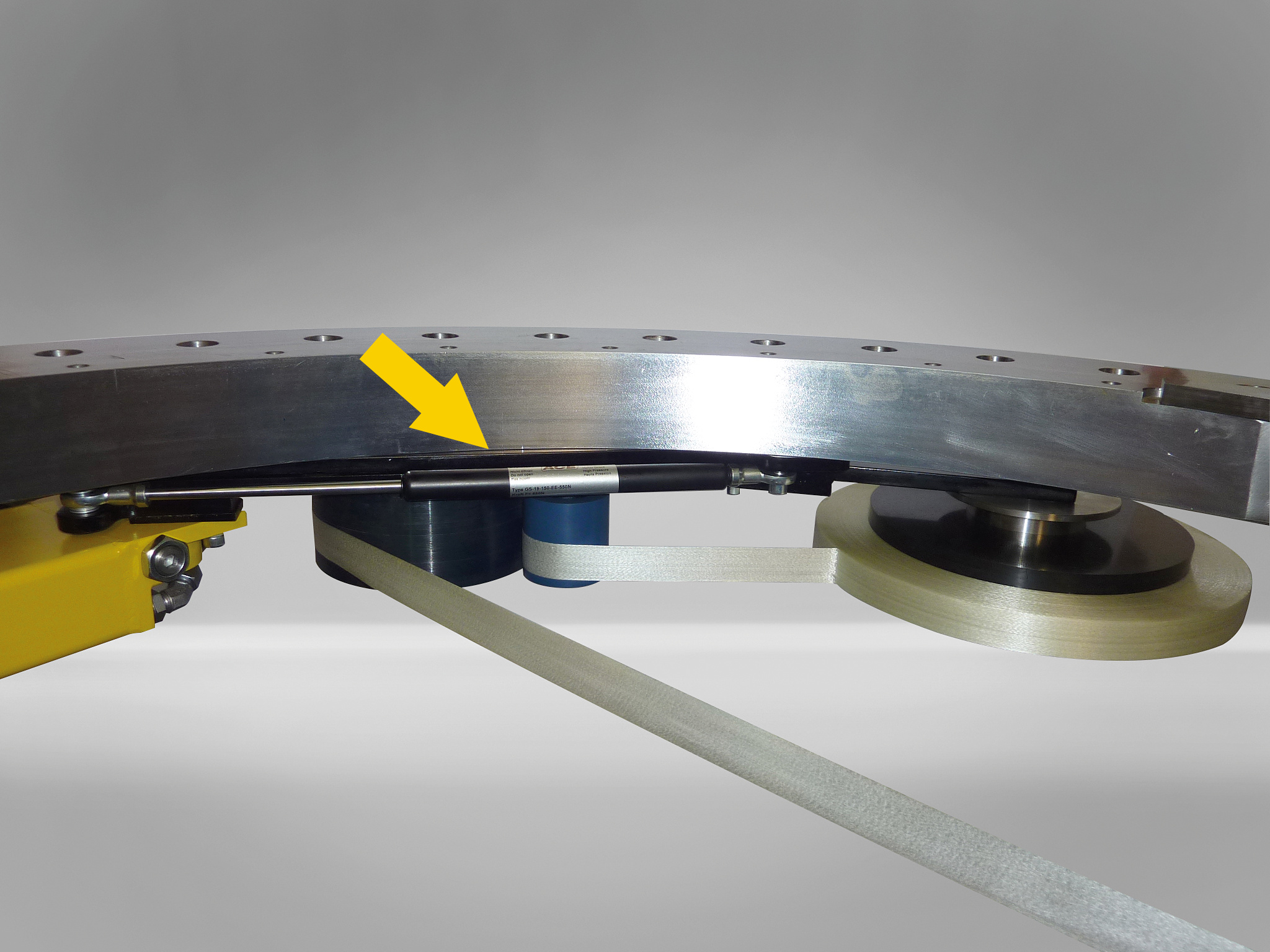

KOHLS winding system with the ACE industrial gas spring to ensure that the tape tension remains constant

Copyright:

KOHLS Maschinenbau GmbH, 63579 Freigericht, Germany

KOHLS winding system with the ACE industrial gas spring to ensure that the tape tension remains constant

Copyright:

KOHLS Maschinenbau GmbH, 63579 Freigericht, Germany

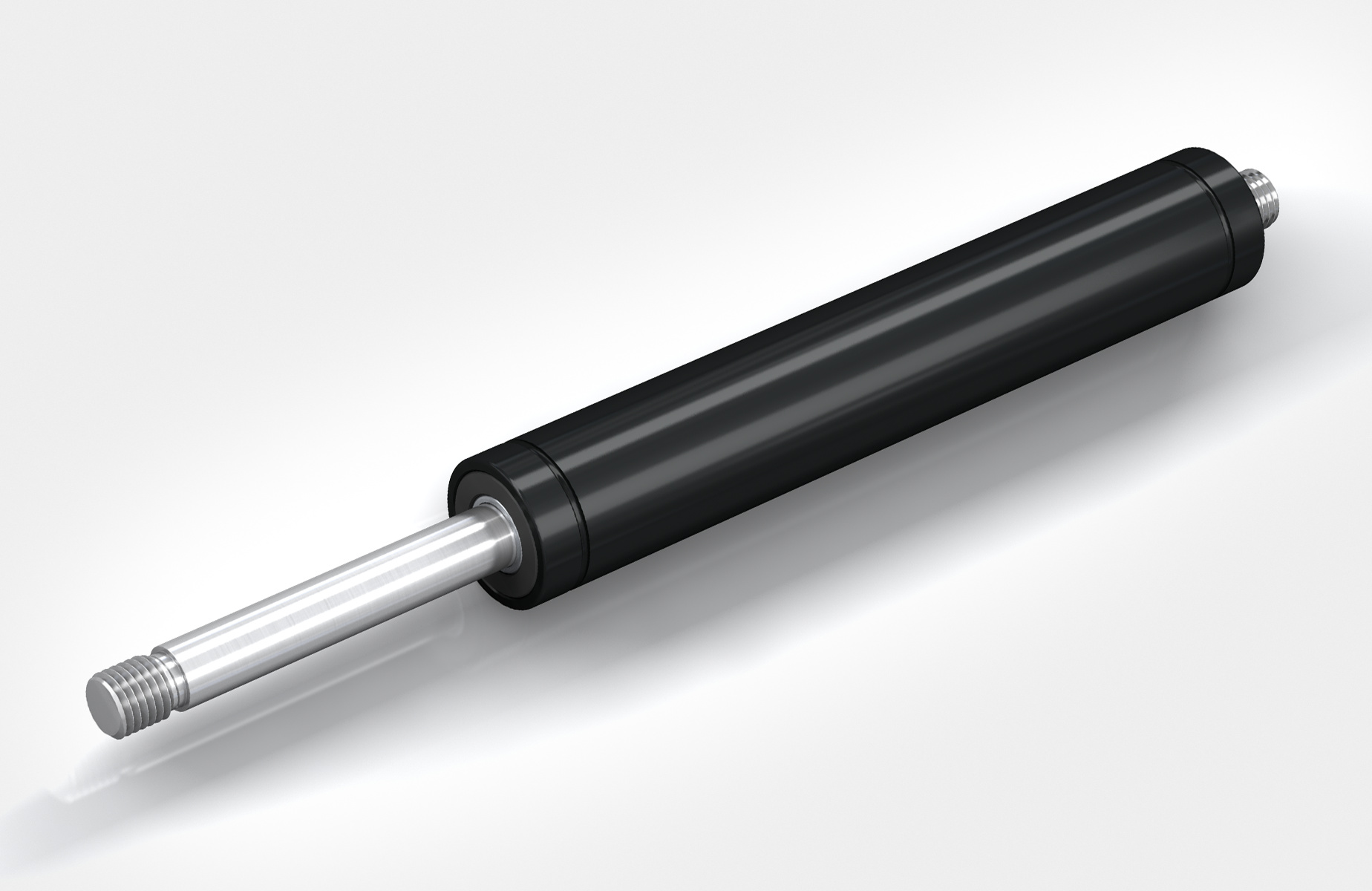

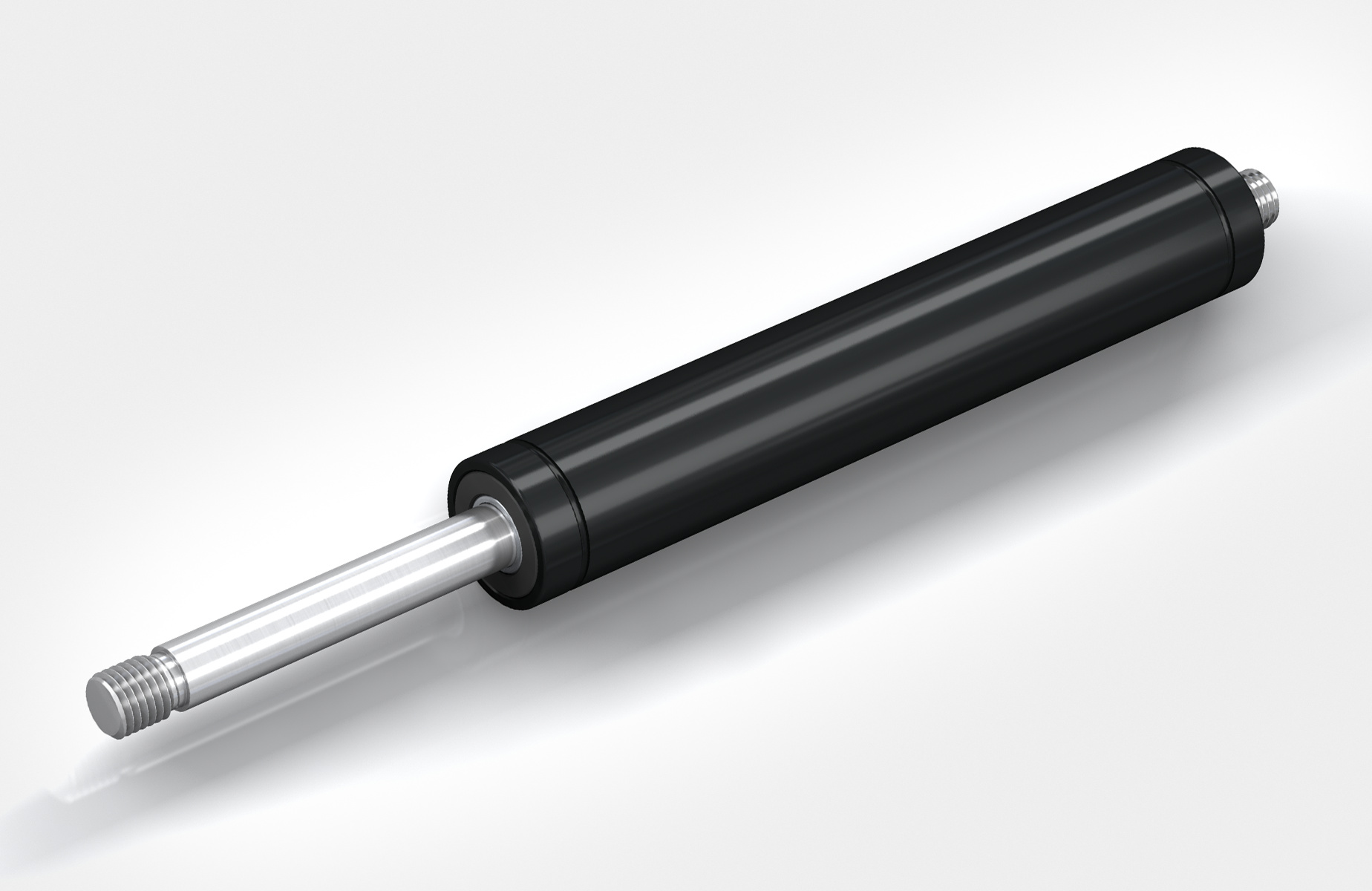

Industrial Gas Springs – Push Type GS-8 to GS-70

Industrial Gas Springs – Push Type GS-8 to GS-70

KOHLS winding system with the ACE industrial gas spring to ensure that the tape tension remains constant

Copyright: KOHLS Maschinenbau GmbH, 63579 Freigericht, Germany

Mech. Engineering & Automation

machines and plants, electro-technology, electronic systems and controls, production plants

Innovative winding system for transformer cores uses ACE push type gas springs for optimum strap tension

When winding a transformer core with resin tape, oval transformer legs can potentially cause a drop in tension. However, the tape tension is highly significant. In order that the sheets in the transformer do not move a millimetre in the vertical direction during winding, a braking system with GS-19 gas springs (push type) from ACE is used. Thanks to its 150 mm travel distance serving as a reserve, the tape tension is kept constant, even in the event of interruptions caused, for example, by almost right-angled cross-sections. This ensures that the winding of the transformer core, which can weigh up to several 100 metric tons, is uniform and even.